Marwe Sports needs no long introduction.

The company had long established itself as a golden standard in rollerski making, and when it talks of “feeling of skiing” – it’s more than a corporate slogan, it’s something many a national team, both in xcskiing and biathlon, can attest to.

In order to understand how, in our rapidly changing world, Marwe manages to remain such a symbol of quality – and fun – the Daily Skier has traveled to the birthplace of Marwe skis.

Well, two places, actually.

Because flagship Marwe skis, 620 XC are assembled in two locations. Here’s what we found & learned.

…Marwe’s marketing manager Paul Fletcher inspects a plywood/Nomex combo core of the future rollerskis at the Peltonen factory in Heinola where all composite platforms are made.

Paul is in many ways a symbol of the modern world that has grown so compact yet remains so diverse: born to British parents, he grew up in Finland, studied in Russia – and speaks at least four languages fluently. And not just speaks – more importantly, he “digs” the nuances of mentality of skiers from the different parts of the world!

Video shows its best. These two gentlemen are launching the process of turning billets into eventual pairs of flashy ( color-wise, function-wise – and yes, price-wise) rollerskis.

The wooden core is reinforced by carbon sheets. Clearly, no UHMWP a.k.a. P-TEX used in snow skis’ glide bases here

Ready-for-assembly platforms are then shipped to Marwe’s own factory at Hyvinkää , some 100km from Heinola

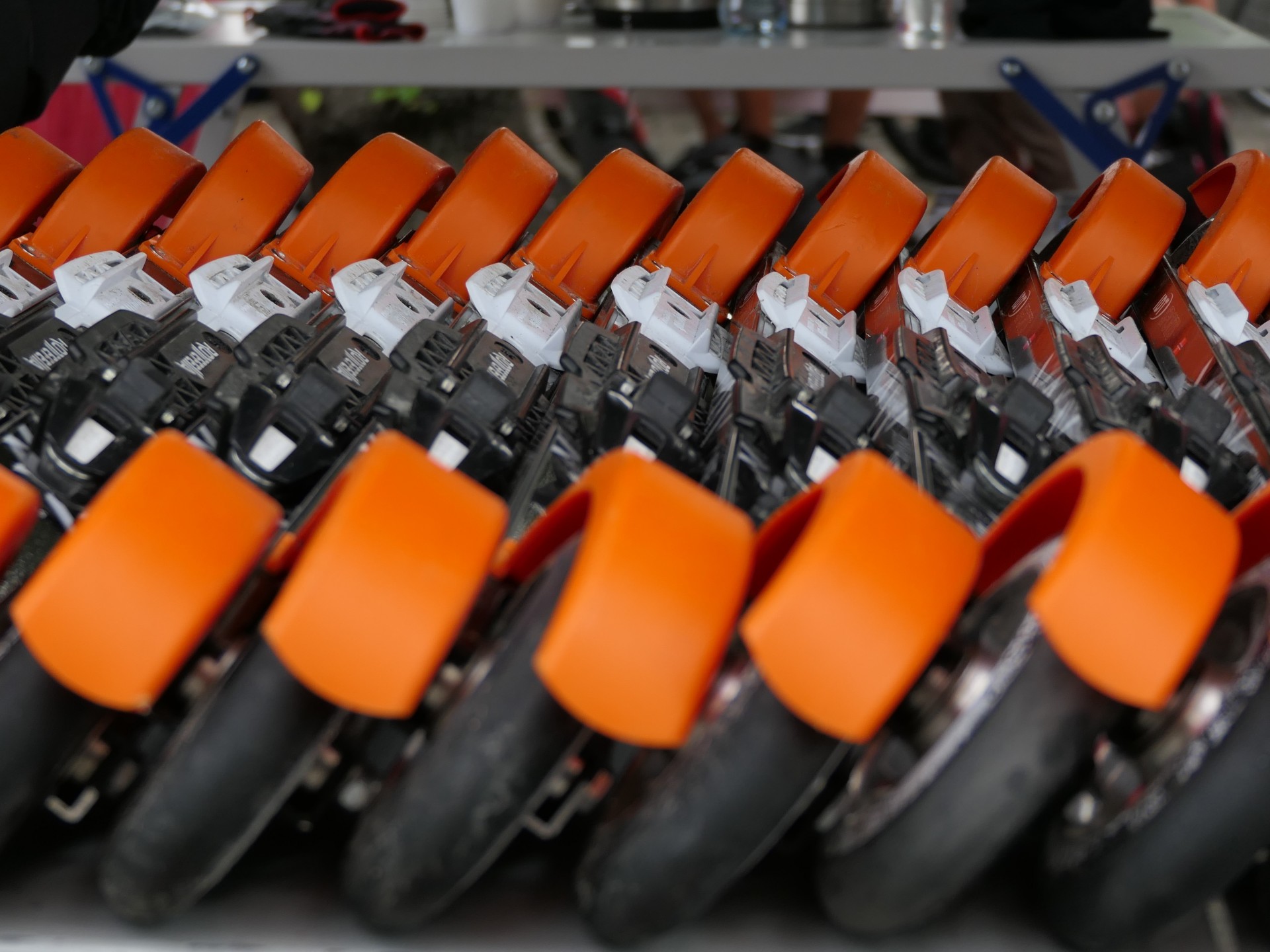

Identical wheels are attached to both composite platforms that come from Peltonen, Heinola – and metal ones produced elsewhere.

Pekka Korpela, CEO of Marwe; Timo Toikka, sales manager Normark,

Paul Fletcher, Media & marketing manager at Marwe; Jarmo Pilli, Peltonen production manager