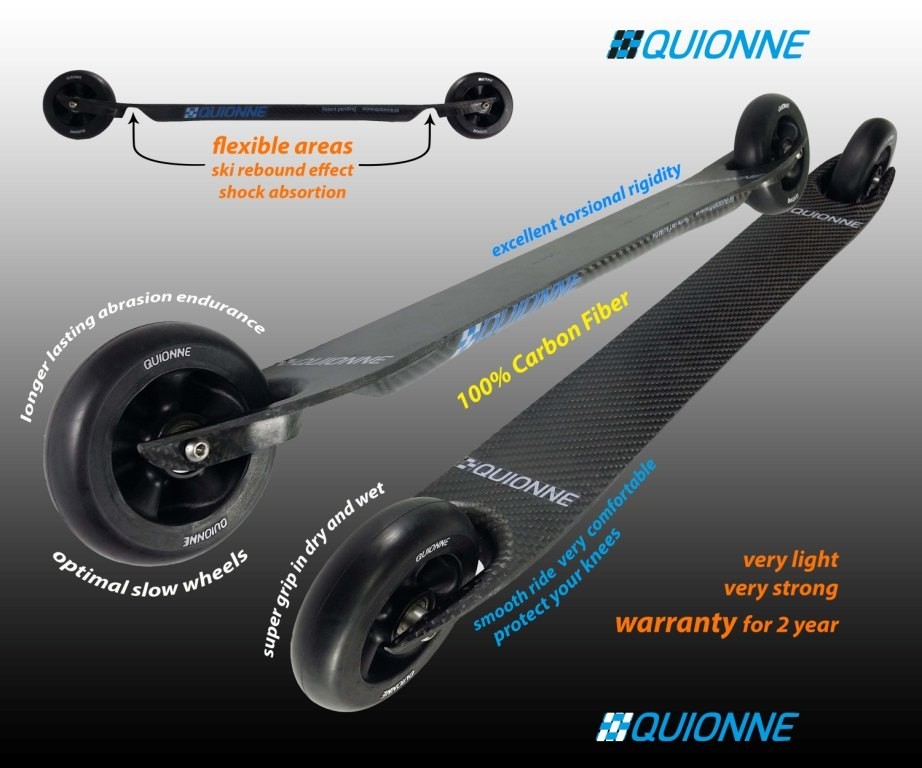

…Which pair of rollerskis has the most striking looks? Not weight, balance, performance – those things are not immediately obvious – just looks? Here at the Daily Skier we vote for Quionne Carbon Fiber. Amazing piece of carbon fiber monocoque, looking somehow more like a powerful bow than rollerski. A total keeper, looks-wise! But is there a substance to go with that chiseled form?

We got in touch with Marcos Rupérez, Quionne Tech S.L. co-founder/co-owner. And guess what? – contrary to expectations, our conversation went all about the substance – never the looks, never that Oomph! factor. Perhaps, because Marcos is not a marketologist or a salesman – he studied industrial engineering, has an MSc in renewable energies and an MBA. And he really, really does not mince his words. Enjoy:

– How did Quionne come into being? What are your aims and your story so far?

– Victor ( Victor Lobo Escolar, a Spanish biathlete and co-founder of Quionne) and me have had come up with an idea of creatimg Quionne when we saw qualities of the rollerskis on the market and their low similarity to skiing. So we decided it would be really good idea to design rollerskis that simulate the snow and ski behaviour as close as possible. Initially, so Victor would be able to train for the IBU World Cup – but afterwards we have decided that the product was good enough to patent it and make a business out of producing them.

Our aim is to be the leading brand of the high quality rollerskis, we strongly believe that we

have a much better product than all the rest on the market, so with the correct partners and marketing we should become the leader on the high-end rollerski products.

The difference between us and competition is that we are an engineering company… most of rollerski companies are not like that – they just copy one another or let their Chinese

factories do their carbón fiber designs…we control both design and production

ourselves.

Quionne is not only about rollerskis – we are doing engineering projects, actually we are

quite successful – for example, we were contracted to design the first everelectric car to participate in the Dakar rally race : yes, this is a Quionne design!. The engineering now brings most of the money- the rollerski business by itself is not profitable yet, because we had to invest a lot in developing and patenting – but we expect it would all pay off in 2018.

This year is a year of change year for Quionne: our first years we were manufacturing

prototypes by ourselves but now we went forward to a more industrialized business model and will launch a full assembly line for our rollerskis at Composites Aragon – based on the process for carbón fiber injection we designed. At the same time, We just signed an agreement with a big distributor , operating in Norway, Sweden, Denmark and Finland, who is now launching our product in those countries.

– How did you learn making carbon fiber monocoque rollerskis? Only a

couple of Italian companies make them – but Italians have huge experience with carbon , from cars to bikes?

– It might sound crazy but we learned it by doing it. Our first prototypes were entirely hand-

made and the last 2 years we have developed our own process and injection molds so

correct balance of quality vs production expenses is achieved.

It was a really difficult and time and money intensive process, but we ended up with a really creative process that allows us to produce our carbón fiber products in Europe!! No one else is capable of doing that while staying competitive price-wise. All the other carbón fibre rollerskis you buy on the market are Chinese-made or from some other Asian countries. From the start Victor and I resolved to produce in Europe and we finally got it.

– Were you trying to create the world’s most visually appealing rollerskis?

– We were trying to create the best rollerskis ever and we think we got it. We try to do the rollerskis that better simulate qualities and actual behavior of snow skis … and our flexible reactive Flexion system is amazingly close to feeling as if you were to be on the snow.

– If you were to choose one word – what’s the best advantage of Quionne Carbon Fiber Skate over carbon laminated frames? And over rival monocoque ones?

– The important thing is not the carbón fibre, I would not buy other carbón fibre rollerskis… there is no advantage in those ones.

Our rollerskis are real flexible and reactive, these are the only rollerski on the market like that. Our competitors’ rollerski absorb the energy while ours store the energy and then return it, springlike – just like snow skis. They are made of carbón fibre because this is the only material capable of storing the energy ( using our patented Flexion sуstem ) without

breaking. So, we didn’t just go for carbón fibre – it’s just that carbón fibre as material was the only solution for our invention.

– Where does the word Quionne come from and what does it mean?

– Quionne is an alternative spelling of Chione/Khione – the Greek goddess of snow and female personification of winter .

– How’s your wheels for wear & tear? And can Quionne Carbon Fiber Skate be had with fenders (mudguards) – or are they solely “good weather rollerskis”?

– We have designed our own wheels but they are not on the market yet, those ones will be a

revolution, we think! At the moment we don’t have enough funds for all the molds and

everything else needed to produce the wheels.

– So, now we are selling same wheels as most of the other rollerski manufacturers –

almost every rollerski manufacturer is buying the rubber wheels from the same

manufacturer. So our wheels now are exactly same wheels as those used by Swenor, for

example, but we hope next season we got financing to finally produce our own

ones that are already designed and tested and are much better.

Mudguards are coming with the next redesign – if you want them now, you’d would have to drill the frame.

– You declare: “Carbon Fiber Skate XL -good for up to 120kg”/ Did you really find a

tester that…chunky? How long did that particular pair last after his/her “test”?

– We do engineering test… look this video:

– Question we’ve had ourselves and heard other asking many times: “The forks look so flimsy. Do they break?”

– The statistics are these: WE HAVE NEVER EVER HAD A SINGLE ROLLERSKI BREAK!!

Why? Because carbón fibre is a very strong material , and because we don’t design really light rollerskis, this is not our claim.

The people have the feeling that carbón fibre rollerskis breaks because most of the manufacturers try to do their rollerski as light as possible so they use a minimum amount of carbón fibre – really thin layers – so finally they break.. But this would also happen with aluminum frames if thee use same design criteria.

We think this is stupid so we designed our rollerskis from the bottom up so they would never break – we use more carbón fibre .. that is all. The weight of the rollerski is not on the chassis – it’s mostly wheels and bindings. So, we increase the weight of our chassis by 10g so it never breaks…that is all!

– Do you work together with another Spanish rollerski start-up, Bonés Skiroll?

– Jorge Vidal ( the boss of Bonés) is a good friend of ours, but we are working for different skiers. He offers a product similar to other brands but at better prices. He offers “a

marwe” or “a swenor” = but with 50% lower price… which is really nice!

But what we at Quionne offer is something new… something that is 3 times better on quality, performance than rollerskis from other brand. We offer something special, innovative, something revolutionary… we have our own patents and design. … it is a different business.